Grismir® Generator & Motor Applications

Thor Power™ Trezium® Electric Motor (Fig. 1).

Our Brushless Alternating Current (BLAC) three-phase motor is slotless, sensorless with permanent magnet rotor, providing smooth variable speed over the complete rpm range from start-up to 30,000rpm, unlike the ratcheting trapezoidal step function of a Brushless Direct Current (BLDC). The motor can also be used as a generator for wind, solar and hydro applications. The motor is scalable, the design principle / techniques of the motor and controller system can extend to 25kW or beyond in a light weight, extremely powerful, efficient package.

Our Brushless Alternating Current (BLAC) three-phase motor is slotless, sensorless with permanent magnet rotor, providing smooth variable speed over the complete rpm range from start-up to 30,000rpm, unlike the ratcheting trapezoidal step function of a Brushless Direct Current (BLDC). The motor can also be used as a generator for wind, solar and hydro applications. The motor is scalable, the design principle / techniques of the motor and controller system can extend to 25kW or beyond in a light weight, extremely powerful, efficient package.

Grismir® Generator Specification ![]()

The consequence of this development is reflected in our tag line,

“Twice the power, half the weigh, double the efficiency.”

The Trezium® System represents a paradigm shift for design of future products in the 21st Century. This is best demonstrated in Thor Power’s initial product offering a NEMA 34 BLAC motor (Fig. 1, above) capable of delivering ¼ HP to a top rating of 2.67HP, at variable speeds up to 30,000rpms. Uses for the Trezium® System are inclusive of Vdc applications, for example, HVDC data facilities and applications on all electric aircraft of the future. In fact, think of where motors are used today, and many places where they are not and the Trezium® System can find a home, for example, Aerospace & Defense, Automotive & Transport, Health Care Products (Medical Devices, Medical Equipment & Supplies), Industrial Manufacturing, Consumer Products Manufacturers, Metals & Mining , Biotechnology, Pharmaceuticals Manufacturers, Environmental Services & Equipment.

When considering areas where motors are not used, think of electric wind and hydro generators.

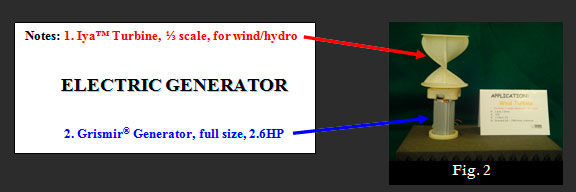

The Trezium® Electric Motor can be used directly as a generator (Fig. 2), without any major modifications or gearing. Therefore, in remote locations the motor can be used as a wind or hydro/wave generator to power lights, electronic systems or pumps for water, gas and petroleum.

The advantages of the Trezium® System represents a paradigm shift for design of energy efficient products for the 21st Century. This is easily demonstrated when considering its use in a power tool application. The angle grinder was the second power tool to be introduced with the advent of the new electric motor in the 1890’s. To date, it has not changed much and that will change with the Trezium® System.

The Thor Power Corporation Grismir® 3000

(see photo, Fig. 3, Grismir® 3000 is the black unit) power tool will achieve lowest total cost of ownership in the market for it’s users. Grismir® provides 2kW of power output compared to the 800W of the green unit. The green unit weighs 13+ lbs. Grismir® weighs 4.7 lbs. Finally, Grismir® 3000 is 84% efficient compared to 47% for the green unit.

(see photo, Fig. 3, Grismir® 3000 is the black unit) power tool will achieve lowest total cost of ownership in the market for it’s users. Grismir® provides 2kW of power output compared to the 800W of the green unit. The green unit weighs 13+ lbs. Grismir® weighs 4.7 lbs. Finally, Grismir® 3000 is 84% efficient compared to 47% for the green unit.

Where air compressors are in use, Grismir® tools can avoid the entire cost of the air system because the patented Trezium® electric controller can be used with any electric current (100 to 267Vac, 50/60Hz; 120 to 380 Vdc) in the world through a simple plug change driven by a simple three phase, two pole permanent magnet motor.

The impact is a tool which is 10 times more reliable, 5 times more durable, and with its variable speed, can replace four to five tools being used today, resulting in better tool utilization rates.

Moreover, due to better power control Grismir® vibrates at less than 2.5 meters/sec squared compared with existing units normal rate of 7.5 meters/sec squared. This equates to less carpal tunnel syndrome, and more important, lower musculoskeletal cumulative trauma disorders resulting in lower workman’s compensation cost.

Finally, due to better power control, Grismir® delivers more than 70% use of consumables (grinding pads, cutting discs, wire brushes, buffers), which can reduce operating expense costs by $1000/tool/week, depending on the application.

Another application to consider, window air conditioners and heat exchangers. The double sided drive cabability of the Trezium® System motor combined with our variable speed drive means that both the fan and compressor can be linked to provide true constant temperature while eliminating the need for a second motor in current designs. Using the Trezium® System in HVAC applications in the future will go a long way toward eliminating summer time power surges.

Lastly, it has been Thor Power’s initiative from the outset – before the first line of design was conceived, to achieve lowest cost of manufacture, highest sixth sigma levels, and lean manufacture in both the motor and the electronics, by design. We are confident this objective is being achieved.

Drive Electronics

The front end of the drive electronics consists of a Power Factor Corrector (PFC) running at 57kHz. Running in a Boost configuration, this PFC circuit converts the input AC line voltage to 375Vdc while maintaining a very high power factor. This circuit can operate from 100Vac to a maximum of 264Vac (nominal 120Vac to 240Vac). With suitable modifications to the input protection devices, DC can also be supplied to the drive. In this case the PFC circuit is acting only as a boost converter. The DC input should be in the range of 100Vdc to 375Vdc.

The front end of the drive electronics consists of a Power Factor Corrector (PFC) running at 57kHz. Running in a Boost configuration, this PFC circuit converts the input AC line voltage to 375Vdc while maintaining a very high power factor. This circuit can operate from 100Vac to a maximum of 264Vac (nominal 120Vac to 240Vac). With suitable modifications to the input protection devices, DC can also be supplied to the drive. In this case the PFC circuit is acting only as a boost converter. The DC input should be in the range of 100Vdc to 375Vdc.

The 375Vdc bus supplies power to a three-phase, six switch IGBT inverter. The power section of the inverter is an intelligent Power Module utilizing 5th generation IGBTs with a 600V/50A rating. The power module also contains integrated drivers, short circuit protection and over temperature protection.

Drive to the inverter power module is from an ASIC that provides the basis for the Sensorless FOC (Field Oriented Control) of the motor. This IC provides open-loop startup of the motor to approximately 3,000rpm. From 3,000rpm to design speed, a controlled speed ramp is provided. Above the minimum speed, the FOC algorithm adjusts the drive to the motor in order to optimize the power output. Speed is regulated with a closed loop speed control algorithm that keeps the speed nearly constant from no-load to full-load. The sinusoidal drive voltages are generated using a Space Vector PWM operating at 12kHz. At 30,000rpm the drive generates a three-phase 500Hz output at approximately 200Vac line to line. A limited amount of the mechanical energy from the motor can be regenerated into the DC buss upon deceleration. This ASIC also monitors fault conditons such as over/under voltage of the DC buss, loss of a motor phase, improper startup, over-current, over-speed, etc

Supervisory control in the drive is handled by a separate dedicated microcontroller. This microcontroller monitors the input voltage, the DC busss voltage, as well as fault registers within the control ASIC. Higher level control algorithms such as output power levels, temperature controlled functionality, cool down timers, etc. can be custom programmed into this microcontroller. Heatsink temperature is monitored and shuts down the drive if the maximum temperature is exceeded.

Motor

The motor in the Trezium system is a 2-pole, three-phase slotless permanent magnet synchronous motor. Provided with adequate cooling, the motor is designed to produce 2kw output at the rated speed of 30,000rpm. Iron-neodymium-boron magnets are used to form the 2-pole rotor. Three fully pitched coils electrically connected in a star configuration from the stator field. These coils are wound using several parallel strands to minimize copper losses. The slotless back-iron assembly is composed of very thin non-oriented silicon steel laminations which minimize core losses. An aluminum extrusion is heat shrunk onto the back-iron assembly to provide cooling. A single PTC thermistor is embedded into the windings to provide motor over-temperature feedback to the drive electronics.